160-year-old German electrical wholesaler chose AutoStore robotics

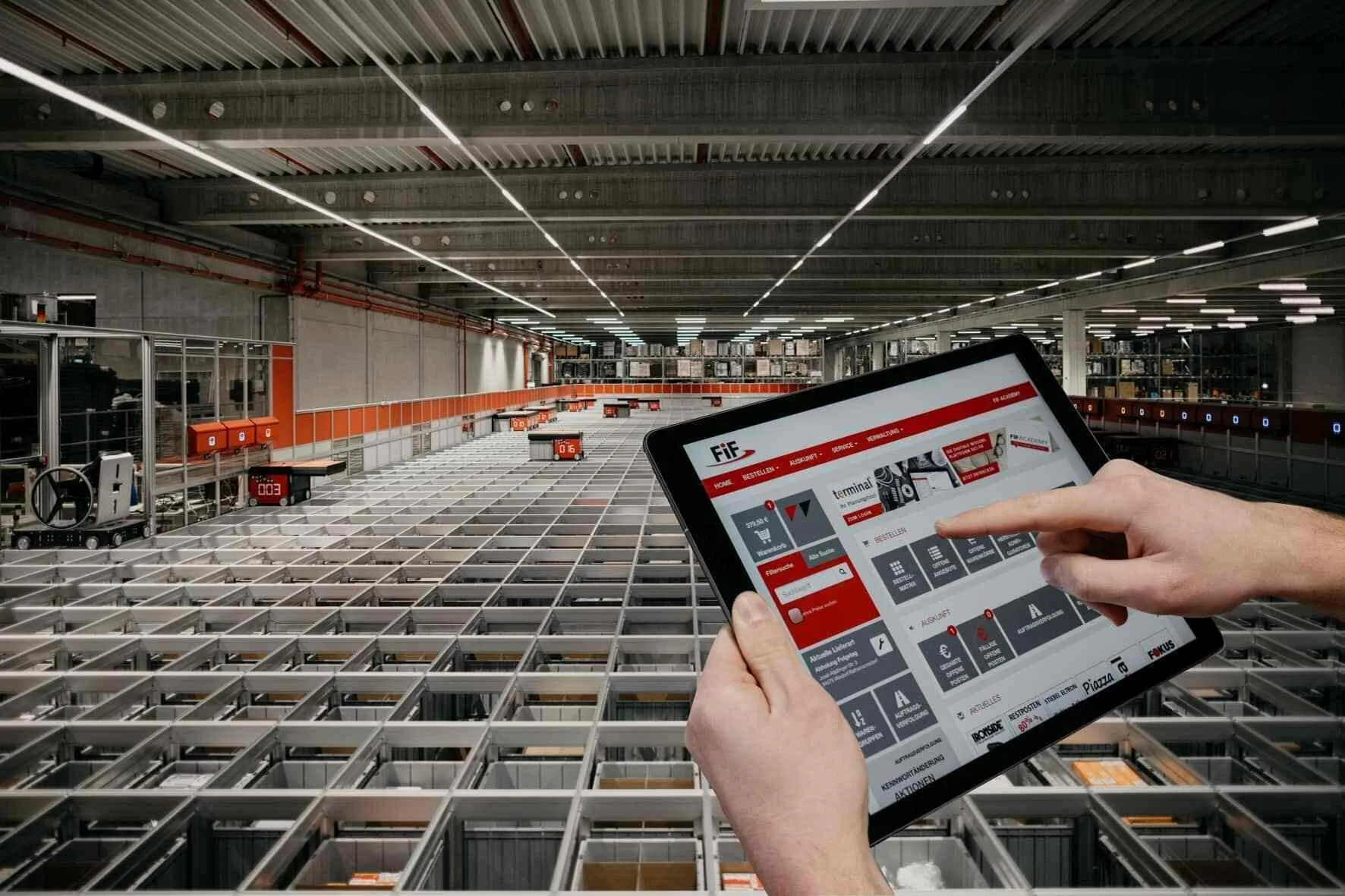

Using the customer-specific ERP system and the AutoStore routing software, the robots immediately remove the storage containers containing the requested items. (Image: H. Gautzsch, Bavaria)

“For the handling of small parts AutoStore is in our opinion the best solution available on the market”

AutoStore robots in action

Founded more than 160 years ago in Muenster, the H. Gautzsch group of companies specializes in wholesaling a wide selection of small electronic and hardware goods and ships to 79 locations nationwide. The company has a total of 1,300 employees and generates sales of more than EUR 450 million in 59 H. Gautzsch companies.

To maximize its logistics and omni-channel capabilities, the German electrical wholesaler is always looking for the use of state-of-the-art technologies. Company processes are continuously studied, optimized, or automated to help facilitate the handling of goods from its network to customers. The continuous search for a sustainable and flexible automated solution for the storage and retrieval of small parts led H. Gautzsch to finalize their choice on the AutoStore robotic technology for the new South-Central warehouse located in Passau, Germany, near the Austrian border.

At the new South-Central warehouse, more than 30,000 electronic parts are available to customers on a quick ship basis. Parts examples include LED lighting items, components for new smart homes, and electrical switching gear for larger construction projects. H. Gautzsch believes, the Rathsmannsdorf logistics center will provide the highest level of efficiency and service levels for the flow of goods from storage to order picking and outbound to customers. From the Rathsmannsdorf facility, H. Gautzsch ships within a radius of 70 kilometers and is also responsible for shipments to Bavaria and in neighboring Austria. In addition to the regular wholesale business, e-commerce and product-related to safety training in the electrical sector are becoming increasingly popular with customers.

On top of the AutoStore« construction called "Grid", robots ensure the fastest possible transport of goods from the warehouse to the picking. (Image: H. Gautzsch, Bavaria)

AutoStore works well for small parts resulting in high space utilization

H. Gautzsch customer requirements are very demanding with the rapid growth of product selection especially in the small electrical parts sector. The need for additional warehouse space is very expensive and comes at the expense of cost-reducing programs which means the company is always looking for ways to improve storage and orderpicking methods while helping the warehouse employees being more productive when processing customer orders.

The search for a long-term, affordable and easily scalable alternative to the traditional shelving system led H. Gautzsch managing director Helmut Lindinger finally to the AutoStore robotic concept. The logistics experts of H. Gautzsch visited existing AutoStore systems in the logistics industry and quickly decided to move ahead with their first project in the central warehouse Elektro-West in Münster.

“AutoStore meets all the requirements that a logistics solution has to offer. Goods are stored without any waste, thus reducing the total space requirements. The system can be easily extended in various modules, is less prone to failure than other concepts, and offers a high degree of operational reliability”

AutoStore meets all expectations with a simple concept and high flexibility

H. Gautzsch's managing director thinks AutoStore in a simple concept which fully meets their expectations and quotes the newly constructed South-Central Warehouse as an example. The AutoStore system measures 7.50 m high and is divided into a aluminum grid solidly constructed. All goods are stored in standardized containers, which, depending on the design of the system, offer volumes of 48, 75 or 99 liters, with a maximum payload of 30 kilograms each. The containers are stacked in the vertical channels of the grid, on the horizontal plane. The bins are spaced by only a few centimeters which means the AutoStore system maximizes the available space in all four cubic directions.

“With the AutoStore robots, we were able to triple productivity by no longer having to take the requested articles one-by-one from shelf storage bins, but automatically sending them to the workstations. At maximum utilization of the existing storage area, this also means a noticeable reduction in work for the approximately 40 employed employees, who spend up to 80 percent of their capacity on handling small parts”

AutoStore Systems can store between 1,000 and more than 1,500,000 containers, depending on the design. In the South-Central warehouse, H. Gautzsch has integrated a system that, with a storage height of approximately 5.5 m and a floor space of around 17 x 46 m. The system can handle a total of 22,000 storage containers with a volume of 75 liters each.

The storage and retrieval of the individual containers takes place centrally from the top. There are compact robots in use, which control each cell of the grid via rails and can remove the topmost container of a cell. Depending on the design, two to more than 600 vehicles are in use on the grid. In contrast to traditional shelves, the storage containers do not have any permanently allocated locations but are dynamically rearranged during operation. Complex software controls the movements and keeps track of the locations of the individual containers. From the number of robots deployed on the grid, the order picking performance of the entire system is calculated: A single robot can average 25 inbound/outbound bins per hour. Outbound orderpicking and replenishment of inbound new goods, takes place from so-called ports, which can be set up anywhere along the lowest grid at floor level workstations.

In conjunction with the customer-specific warehouse management system (WMS), the AutoStore routing software ensures smooth traffic patterns with the modular cell network to minimized the time containers need to reach the desired workstations.

“After the positive experiences with the systems installed so far, the H. Gautzsch group of companies hardly wants to do without AutoStore. In cooperation with AM-Automation, the establishment of further systems at different locations of the company is already under discussion”

Source Article: Beitrag Vom @ i-magazin.com on November 27, 2019