New slick Robot keeps a sharp eye on busy construction sites

Buildings under construction are a maze of half-completed structures, gantries, stacked materials, and busy workers — tracking what’s going on can be a nightmare. Scaled Robotics has designed a robot that can navigate this chaos and produce 3D progress maps in minutes, precise enough to detect that a beam is just a centimeter or two off.

Bottlenecks in construction aren’t limited to manpower and materials. Understanding exactly what’s been done and what needs doing is a critical part of completing a project in good time, but it’s the kind of painstaking work that requires special training and equipment. Or, as Scaled Robotics showed today at TC Disrupt Berlin 2019, specially trained equipment.

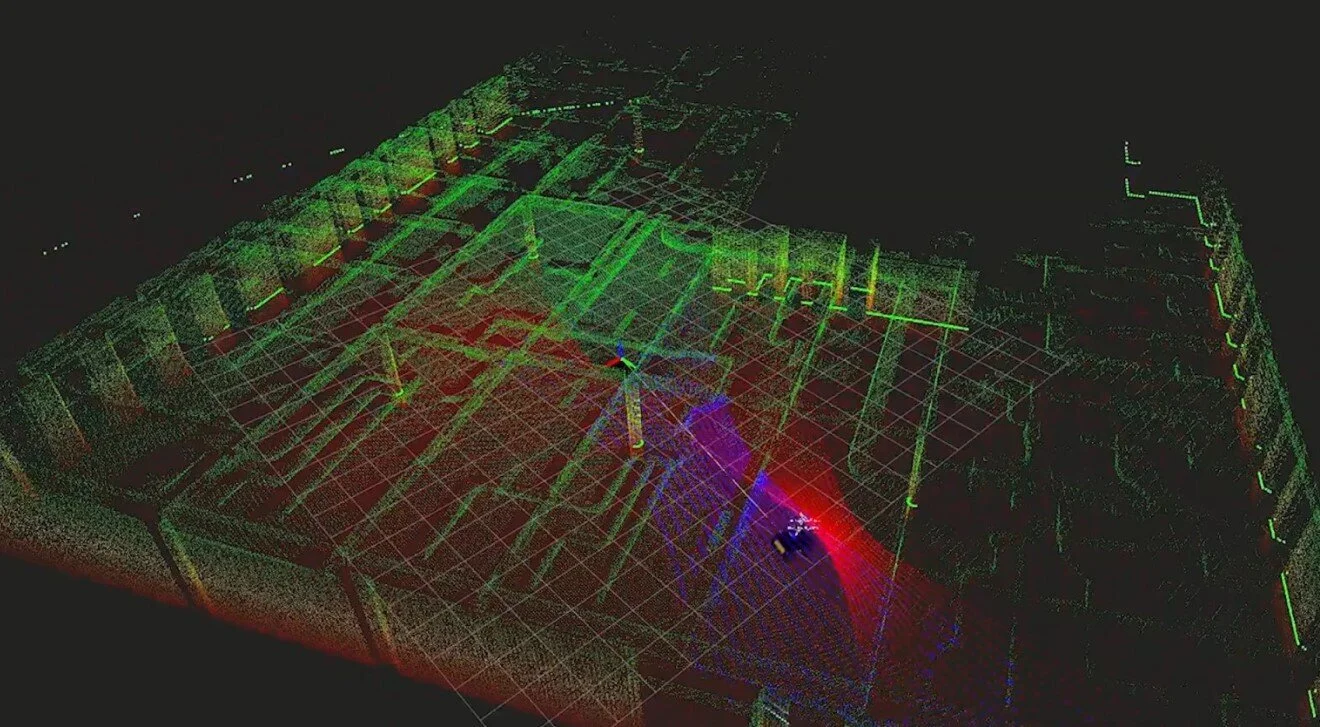

The team has created a robot that trundles autonomously around construction sites, using a 360-degree camera and custom lidar system to systematically document its surroundings. An object recognition system allows it to tell the difference between a constructed wall and a piece of sheet rock leaned against it, between a staircase and temporary stairs for electric work, and so on.

By comparing this to a source CAD model of the building, it can paint a very precise picture of the progress being made. They’ve built a special computer vision model that’s suited to the task of sorting obstructions from the constructions and identifying everything in between.

But the founders emphasized that tracking progress is only the first hint of what can be done with this kind of accurate, timely data.

“The big picture version of where this is going is that this is the visual wiki for everything related to your construction site. You just click and you see everything that’s relevant,” said Sankaran. “Then you can provide other ancillary products, like health and safety stuff, where is storage space on site, predicting whether the project is on schedule.”

“At the moment, what you’re seeing is about looking at one moment in time and diagnosing it as quickly as possible,” said Maggs. “But it will also be about tracking that over time: We can find patterns within that construction process. That data feeds that back into their processes, so it goes from a reactive workflow to a proactive one.”

“As the product evolves you start unwrapping, like an onion, the different layers of functionality,” said Sankaran.

The company has come this far on $1 million of seed funding, but is hot on the track of more. Perhaps more importantly, its partnerships with construction giant PERI and Autodesk, which has helped push digital construction tools, may make it a familiar presence at building sites around the world soon.