What Goes Behind the Iconic Amazon Brown Parcel?

Next day delivery is a pretty normal phenomenon, but what goes behind the iconic brown parcel? Daily Star reporter Harry Thompson took to Amazon's warehouse to find out.

Getting a parcel on the same day you clicked ‘buy’ seems like a modern miracle to most, but in the guts of Amazon's operation it makes perfect sense.

In a world where time is scarce and money scarcer, being able to order a bargain blender in time for tomorrow’s smoothie seems incompatible with today’s trend of less for more.

But, after a day on the line in one of Jeff Bezos’s largest UK facilities in the run up to Black Friday, I quickly learned how a morning’s dream can turn into an evening’s reality. Why? Because Amazon prays to one god – efficiency.

The glamorously-named EMA4 is the cutting edge of Amazon’s 31 'fulfilment centres’ in the UK, so I headed up to see what a day in the life was like. These key junctions in its supply chain are as close to a traditional shop as it comes in the Amazon universe – stuff comes in from suppliers and waits there until someone wants to buy it.

The scale of the place is astonishing, scary even, and a day on the ‘shop floor,’ as my guide described it, is knackering. I arrived in a taxi from Sutton Coldfield, trundling along West Midlands roads until a massive block filled the horizon. It looked like a spaceship had landed, and in a way maybe it had. Vast straight lines and hard edges became all you could see, like an Ikea if it had eaten Norway on the way over from Sweden.

After getting over my megalophobia in the main office, I braced myself for the chaos ahead. I pictured boxes flying everywhere, errant parcels setting off alarms and a decaying Annabelle doll from three Christmases ago wedged in a conveyor belt letting out its final belches.

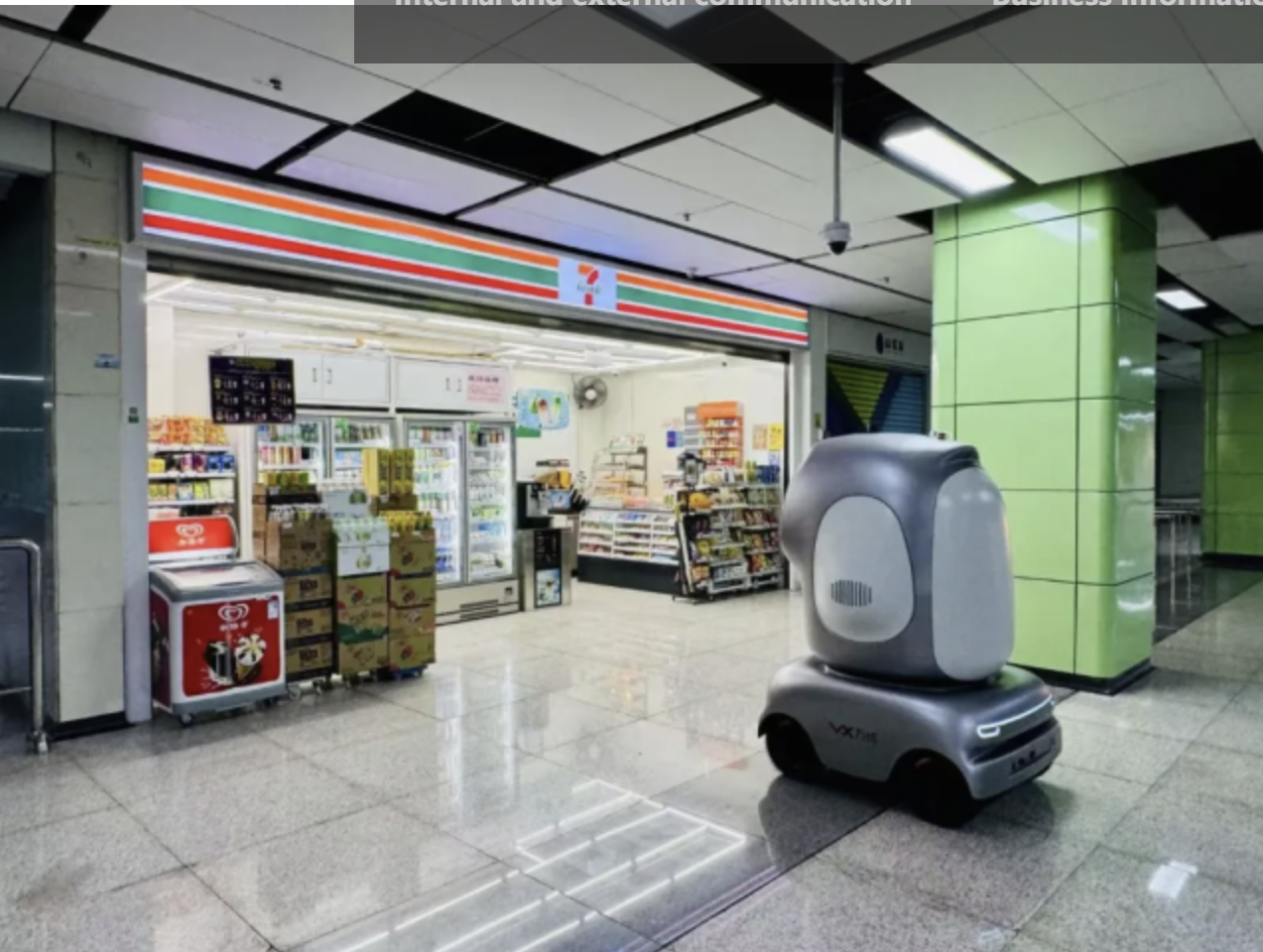

Meet the industry’s most advanced mixed-fleet orchestration platform for automated logistics facilities. Seamlessly integrate your WMS workflows with ASRS, GTPs, conveyors, sortation, mobile robots, forklifts, human workers, etc., onto one open-source platform. It ensures real-time processing, supports any brand, leverages machine learning, and keeps humans in the loop for smarter, more adaptable operations.

Imagine my shock then, when I was met with the tranquil hum of modernity. The shop floor is a strangely peaceful place. Fulfilment Centre EMA4, which stands for East Midlands Airport 4, is divided up into four levels. The back wall of the ground floor is split in half – on the left, lorries dump boxes from suppliers and on the right, they take away neatly packaged orders for little Jimmy in time for Christmas. But what happens in between?

The majority of the stock it deals with isn’t from Amazon directly, but through small businesses – in other words, this cathedral to capitalism isn’t one company filling its boots, but a marketplace filled with the goods of thousands of smaller, independent sellers.

But what is truly staggering is how your order gets from the left side to the right side without the fuss, noise or the chaos you might associate with what my guides called ‘busy season’.

Everything about it was peaceful. First boxes from suppliers are sent to a section called Predicant, where staff break down boxes and put sellers' products into separate containers before sending them off to a place called Stow.

This is where today’s robot-oriented world becomes apparent. Above the ground floor, three identical replicas stack on top of one another, each human-friendly margin encircling a central labyrinth of tightly-packed yellow columns called ‘bins’. Each bin stands around 10-feet tall and stands around 12inches from the ground, filled with everything from books to bin bags.

This central space takes up the majority of each enormous floor, yet there's no one in sight. Inside the margin is the land of the machines, where bots rule and only “highly trained associates” are allowed to enter. They operate on a computer algorithm that either doesn’t have a name – or has one that The Daily Star isn’t allowed to know – and is simply referred to as “the background”. Statements like ‘the robots run in the background,’ or ‘operate on the background algorithm’ were two a penny on my visit.

Robots are king in this great capitalist jungle with technicians, like our guide beyond the wire Darlington, only allowed to enter wearing jackets that look like they’ve been stolen from a Laser Quest.

These jackets emit a signal that prevents the immensely-heavy bots from storming down the narrow corridors and turning technicians – or in this case The Daily Star – into robot roadkill. Think of them as robot omens to ward off danger.

The space is spooky, corridors of commodities stretching as far as the eye can see sitting in deathly silence broken only by the electronic hum of “lots and lots” (we weren’t allowed to publish an exact number) of robots whizzing across passages like a giant game of Pac Man.

Amazon has been using these rolling platforms, which move underneath bins and pick them up from below, for around 15 years, and staff attest that they have maximised efficiency.

But, despite representatives telling me that Amazon Robotics is a positive contributor to employment, it was hard to escape the feeling that so much was happening in a space where barely anyone was around to see it. EMA4 employs around 2,000 people but when we were there felt thin on humanity considering the pre-Black Friday and Christmas busy season.

On the floor below, conveyor belts of goods whizz almost silently by, funnelled down from ‘Pickers’ who take items off the bins delivered to doors at the edge of the central labyrinth by bots.

The Pickers and Stowers’ margins around the perimeter are a pleasant place to work, peaceful with windows running along the edge. Like all staff in the centre, they aren’t allowed to wear headphones, the tranquillity broken by the odd speaker on which staff are allowed to choose the music.

But the Stowers are offered a rare treat in the centre, games that link directly to their output to “keep them engaged”. “This one’s my favourite," one Stower told me with a smile on his face as he loaded up a cartoonish screen filled with rabbits. I’m told there’s no prize, only a leaderboard.

Once packaged up, either here or in conveyor-belt oriented picking zones on the ground floor, parcels move into the Slam section. Despite appearing to slam labels onto parcels using compressed gas, the place actually got its punky title because it stands for Ship Label Apply Manifest, which is slightly less rock and roll.

As each package is given its shipping label, a text is fired off to the customer telling them their order has been dispatched, and from here it runs along a conveyor belt down and chute and into a large container where it awaits its lorry.

Full Story on dailystar.com