Coca-Cola to Double Capacity with New Automated Warehouse

Coca-Cola Europacific Partners is one of the leading consumer goods companies serving 1.75 million customers across 29 countries. Its business generates over €15 billion in revenue, selling more than 3 billion unit cases annually.

Europe’s largest soft drinks plant by volume will see a major investment into an automated storage system.

Coca-Cola Europacific Partners is investing £42.3m into a new automated storage retrieval system (ASRS) warehouse at its site in Wakefield.

The ASRS will take around two and a half years to build and will stand at 38 meters tall to save space and increase the Wakefield’s warehouse capacity.

The new automated system will enable the facility to double its capacity, adding an additional 29,500 pallets to its current capacity of 29,000 pallets, while also reducing its number of vehicle journeys per year by 18,500—the equivalent of 441,000km annually.

This funding follows a £31m site investment for the installation of a new canning line, capable of producing 2,000 cans per minute, which has been operational since July 2024.

The line provides additional production capabilities for CCEP’s light-weight 330ml cans across brands including Coca-Cola, Diet Coke, Coca-Cola Zero Sugar, Fanta, Dr Pepper, and Sprite.

The bottler has also been evolving its approach to recruitment, placing more focus on skills and potential than experience and qualifications. This has seen the site increase its uptake of female workers on the canning line this year, with three of four team leaders on the line being female and a total 40/60 women-to-men gender split on the new line.

“The new ASRS warehouse ensures we continue expanding our production capabilities as we look to the future, and operate as efficiently and sustainably as possible.”

Vanessa Smith, director of Wakefield supply chain operations, CCEP

Wakefield has received £103m in investment since 2019 to enhance efficiencies and operate more sustainably, such as the replacement of its material handling equipment (MHE).

This includes a fleet of 75 gas-powered forklift trucks which are used to move cases of products around the site. These are powered by lithium ion batteries which produce no carbon emissions in their day-to-day operation.

“Wakefield offers a range of modern manufacturing jobs and sits at the heart of many of our latest manufacturing technologies,” said Stephen Moorhouse, VP and general manager, CCEP.

“We’ve invested more than £100m since 2019 to help us evolve operations on site and further support the local economy."

High-Bay AS/RS for Full Pallets: A Comprehensive Guide to Operations and ROI

Key Features:

High-Bay Storage:

Tall racks, often exceeding 12 meters (40 feet), optimized to maximize vertical storage space.

Can store hundreds or thousands of pallets in a relatively small footprint.

Automated Retrieval:

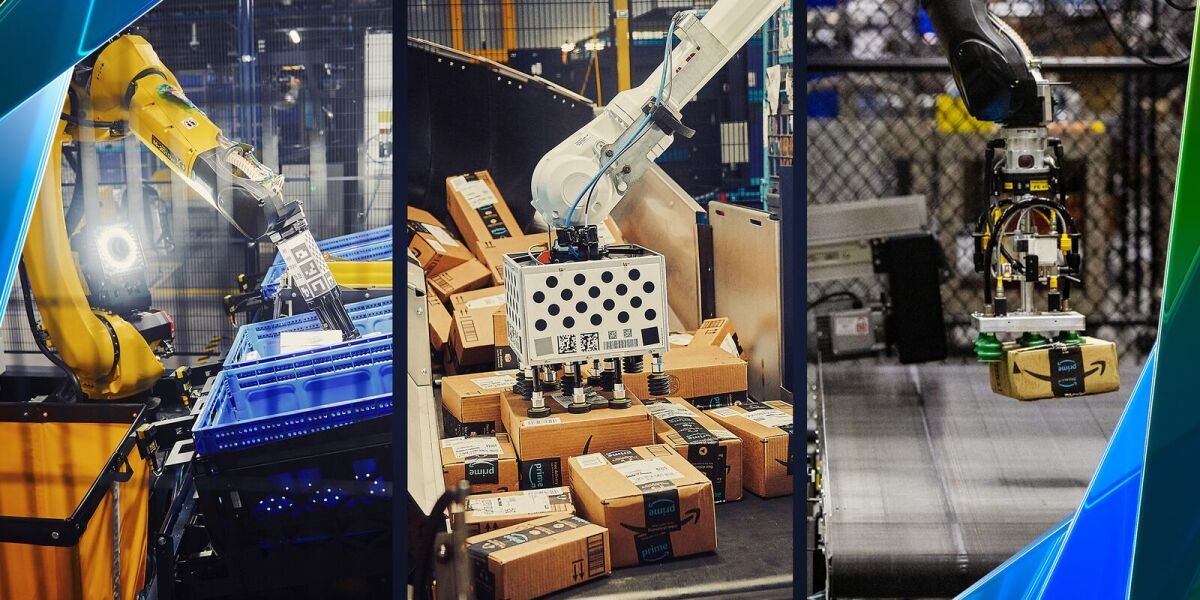

Uses automated equipment like stacker cranes, shuttle systems, or robotic arms to handle pallets.

Pallets are moved to and from storage locations without human intervention.

Integration with Warehouse Management Systems (WMS):

Connected to software systems for real-time inventory tracking, retrieval, and placement.

Handling Full Pallets:

Designed specifically for moving full pallets, making them ideal for applications like bulk storage, manufacturing, or retail distribution.

Components:

Racks: Custom-designed for vertical storage of standardized pallets.

Material Handling Equipment:

Stacker Cranes: Robotic cranes that travel between aisles to pick or store pallets.

Shuttle Systems: Automated carts moving horizontally to retrieve or place pallets.

Conveyors: Transfer pallets to/from the AS/RS to other areas of the facility.

Lifts: Move pallets vertically between different levels of the system.

Benefits:

Space Efficiency: Maximizes cubic storage, reducing the footprint needed.

Labor Savings: Reduces manual handling of pallets, leading to fewer errors and injuries.

Speed and Accuracy: Automates repetitive tasks, ensuring fast and accurate retrieval.

Inventory Control: Real-time tracking ensures stock accuracy and better inventory turnover.

Applications:

Large-scale manufacturing operations for storing raw materials or finished goods.

Retail and e-commerce distribution centers requiring high-density storage.

Cold storage environments where automation minimizes human exposure to extreme temperatures.

Operations of a High-Bay AS/RS for Full Pallets

A high-bay automated storage and retrieval system (AS/RS) is highly efficient, but its operational model depends on careful integration of mechanical, electrical, and software systems. Here's how it typically operates:

1. Receiving and Storing Pallets:

Inbound Process:

Full pallets are delivered to the system via forklifts or conveyors.

A check station (e.g., barcode scanner, weight/size checks) ensures the pallet meets specifications for automation.

Storage Assignment:

The Warehouse Management System (WMS) assigns a storage location based on factors like demand, product type, or FIFO (First In, First Out) principles.

A stacker crane or shuttle system retrieves the pallet and places it in the high-bay rack at the designated location.

2. Retrieving Pallets:

Automated Requests:

Pallets are requested via WMS or an ERP system integrated into the supply chain.

The AS/RS retrieves the pallet using stacker cranes or shuttle systems, often delivering it to an outbound conveyor for processing.

Sequence Handling:

If required, pallets can be delivered in a specific order for loading trucks, production lines, or picking zones.

3. Maintenance and Downtime Management:

Routine preventive maintenance minimizes downtime.

Redundant systems (e.g., multiple cranes per aisle) ensure operations continue even during repairs.

4. Throughput Optimization:

Advanced algorithms optimize crane or shuttle movements to minimize travel time.

High-throughput environments might use dual-load stacker cranes (handling two pallets simultaneously).

ROI (Return on Investment) for High-Bay AS/RS

The ROI for an AS/RS depends on factors like operational volume, labor costs, and the system's impact on overall efficiency. Here's a breakdown of how the investment pays off:

1. Key Costs:

Capital Investment:

Initial costs for hardware, software, and installation are high. Systems can range from $2 million to $10+ million depending on size and complexity.

Maintenance and Upgrades:

Ongoing costs include preventive maintenance, occasional repairs, and software updates.

Energy Consumption:

High-bay AS/RS systems are energy-intensive, but efficient designs and regenerative braking can reduce operational costs.

2. Cost Savings:

Labor Reduction:

Automation reduces dependence on manual labor for pallet handling, especially beneficial in regions with high labor costs.

Typical savings: $300,000–$500,000 annually in labor costs for a mid-sized operation.

Space Optimization:

Maximizing vertical storage reduces the need for additional warehouse expansion or leasing costs.

Savings: $50,000–$200,000 per year depending on local real estate costs.

Reduced Errors:

Automated systems significantly cut inventory handling and picking errors, reducing rework and customer complaints.

3. Efficiency Gains:

Improved Throughput:

Faster pallet handling increases throughput, enabling operations to scale.

Energy Efficiency:

Advanced systems optimize power use, with some achieving up to 30% savings through regenerative technologies.

4. ROI Calculation:

A well-implemented AS/RS typically has a payback period of 5–7 years, depending on the following:

Initial Cost: Let’s assume $5 million for a mid-sized system.

Annual Savings:

Labor: $400,000

Space: $100,000

Error Reduction: $50,000

Efficiency Gains: $50,000

Annual ROI:

$600,000–$700,000 in total savings

Approx. 12–14% ROI annually

With compounding efficiency gains and reduced human error costs, the system becomes highly profitable after its payback period.

Factors to Improve ROI:

Utilization: Maximize the system by running multiple shifts or integrating it into production processes.

Custom Design: Tailor the system to your specific needs to avoid over- or under-engineering.

Energy Recovery: Choose systems with regenerative braking for additional energy savings.

Long-Term Contracts: Negotiate discounts with suppliers and integrators for software updates and maintenance.