JD Logistics Unveils Automated Picking Solution at CeMAT Asia

JD Logistics unveiled today at CeMAT ASIA 2024 its latest Goods-to-Person (GTP) automated warehousing system named the “Zhilang” solution. Meaning “Intelligent Wolf”, Zhilang is a proprietary system that improves picking efficiency when compared to conventional manual methods.

Zhilang” Goods-to-Person (GTP) automated warehousing solution

The Zhilang GTP solution combines several technologies, including handling AGVs, lifting robots, and shelving systems, along with automated inbound and picking workstations and an empty tote reflow line. Leveraging warehouse height, Zhilang increases storage density multiple times the industry average for facilities up to 10 meters high.

The system’s modular design enables AGVs and lifting robots to operate independently. Powered by JD Logistics’ self-developed “upper-tote storage and lower-level picking algorithms and buffer storage” technologies, the virtual network is fully flexible for optimized routing. JD’s high-precision navigation algorithm, dual-direction laser obstacle detection technology, and vision-based safety verification ensure precise retrieval with minimal error.

Zhilang” Lifting Robot and Shelving System

Currently, nearly 100 Zhilang AGVs and lifting robots are in operation at a logistics client in Beijing, handling nearly a million items, from t-shirts to shoes. All orders are directed seamlessly to several GTP workstations. Human pickers then place SKU items directly from the robots into the order totes, enabling an automated order fulfillment process from inbound to outbound.

Zhilang” Handling AGV

JD Logistics offers a wide array of other automated solutions, including the Tianlang Tote Shuttle GTP system, Dilang AGV GTP system, Four-way Pallet Shuttle Storage system, Auto Remin Wall, and the Aidong mobile data terminal. In terms of software, JD Logistics’ WCS (warehouse control system), WES (warehouse execution system), RMS (robotics management system), 3D SCADA (3D supervisory control and data acquisition), and Lomir intelligent logistics park management platform, are used in over 1,600 JD Logistcs-operated warehouses and client facilities.

As JD Logistics expands globally, its solutions serve thousands of corporate clients across dozens of countries and regions, including Poland, the Netherlands, Germany, South Korea, the United States, and throughout Southeast Asia, the Middle East, and beyond.

Amazon has been on a multi-billion dollar and decade-plus long crusade to be a leader in robotics.

Delivery times for Amazon in Quebec have more than doubled on some items following the company’s decision to mothball all of its facilities.

This remarkable achievement is part of Amazon's broader strategy to enhance its e-commerce platform's performance by integrating advanced robotics and a rapidly expanding delivery network.

Amazon employees in Australia, Brazil, Canada, France, and Singapore gave their children an exclusive peek into the magic that happens at Amazon fulfillment centers ahead of Christmas.

The newly published paper found that Amazon's entry in a metro area increased wages, jobs, and home values.

Pour la première fois, Amazon, leader mondial de la vente en ligne, a ouvert ses portes à une caméra de télévision.

NBC News' Vicky Nguyen gets an exclusive look inside Amazon's next-generation fulfillment center in Shreveport, La.

India is one of the fastest growing markets for Amazon’s e-commerce.

The Pickle Delivery Experiment: A Deep Dive into Same-Day Logistics.

Amazon uses a tiered storage system in its warehousing and fulfillment network to manage items of varying sizes, weights, and shapes efficiently.

The glamorously-named EMA4 is the cutting edge of Amazon’s 31 'fulfilment centres’ in the UK.

The 1.2 million square foot fulfillment center in Robbinsville is the size of 28 football fields.

“It’s their second largest in the country,” Virtuoso said of the 3.1 million-square-foot facility.

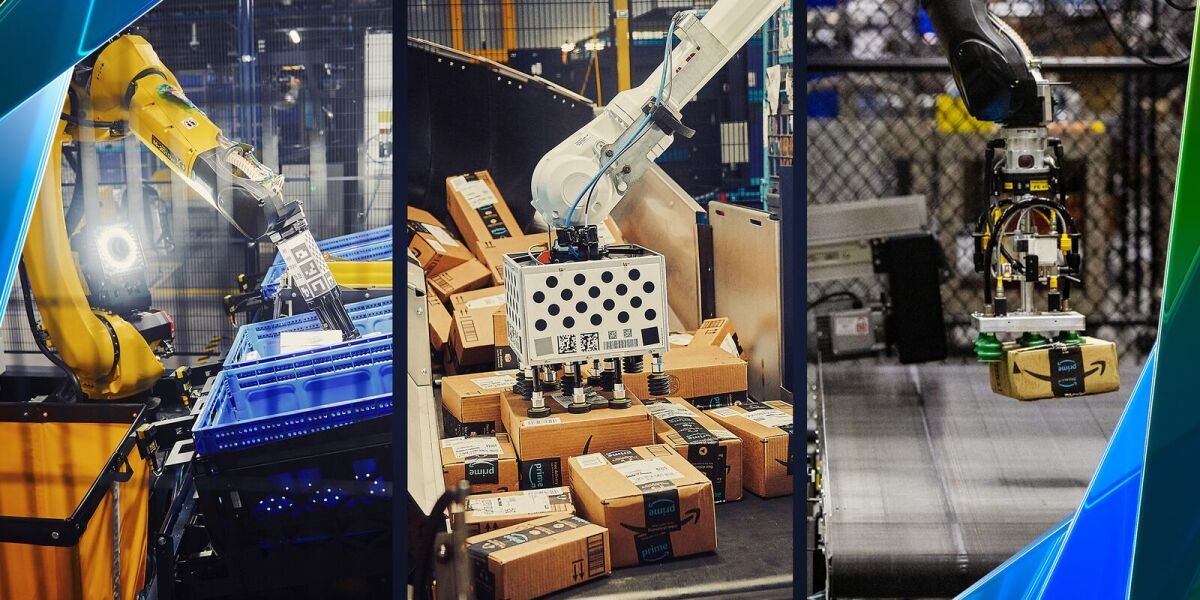

Amazon has introduced a handful of new robots to improve efficiency and reduce employee injuries.

The journey of a package from the moment a customer clicks “buy” is one of the most complex and finely tuned processes in the world of e-commerce.

Watch Amazon’s first fully autonomous mobile robot

A new AI-powered solution, delivery drivers will no longer have to spend time organizing packages

Amazon’s efforts to improve inventory placement are bearing fruit while more investments are underway.

Last week, Amazon announced it is testing a robotic concept at one of its Whole Foods locations in a Philadelphia suburb,

Sequoia allows Amazon to identify and store inventory received at its fulfillment centers up to 75% faster than we can today.

Last week, Amazon announced it is piloting a new concept at one of its Whole Foods locations in a Philadelphia suburb, where a micro-fulfillment center will be bolted onto the store and allow shoppers to purchase staples not typically stocked by the organic grocer.

Amazon is adding robot warehouses to Whole Foods so shoppers can pick up other orders at checkout.

Amazon unveils the next generation of fulfillment centers powered by advanced AI and 10 times more robotics.

The 4.5 million-square-foot, six-story facility has more than 7,000 robots.

Learn about Amazon's 750,000+ robot fleet and the future of human-robot collaboration.

CNBC got an exclusive look at Amazon’s use of generative AI to optimize delivery routes.

The Washington State facility employs 2,500 people and can store 40 million items.

Employees at its warehouses across the U.S. have alleged unsafe working conditions, and they fret over job security in the age of artificial intelligence. Amazon’s chief technologist, Tye Brady, disputes both counts.