Irving Paper Announces Major Plant Expansion Featuring Fully Automated Warehouse

The facility currently employs more than 400 people and will grow with new production capacity and a new automated warehouse.

Irving Tissue unveils a $600 million expansion project at its Macon, Georgia plant. From left to right: Robby Fountain, Board Chair of the Macon-Bibb County Industrial Authority (MBCIA), Pat Wilson, Commissioner of the Georgia Department of Economic Development (GDEcD), Robert K. Irving, President of Irving Tissue, and Grover Hardin, Plant Manager of Irving Tissue Macon. (Photo: MBCIA)

Canadian paper products maker Irving Tissue plans a $600 million expansion of its factory in Macon, a project that will also create at least 100 jobs, the company and state officials announced Thursday.

Irving Tissue said it needs to expand in Macon because the mill is currently selling all the bath tissue and paper towels it can make. The privately held firm will add a third paper machine, increasing output by 50%.

“We’ve had tremendous success in Macon and with the plant currently sold out, this is the right plant for the expansion.” Marc Doucette, Irving's vice president of communications, wrote in an email.

The company, which currently has 400 workers, announced the plan Thursday as it celebrated the fifth anniversary of the mill, which makes private-label products for retailers.

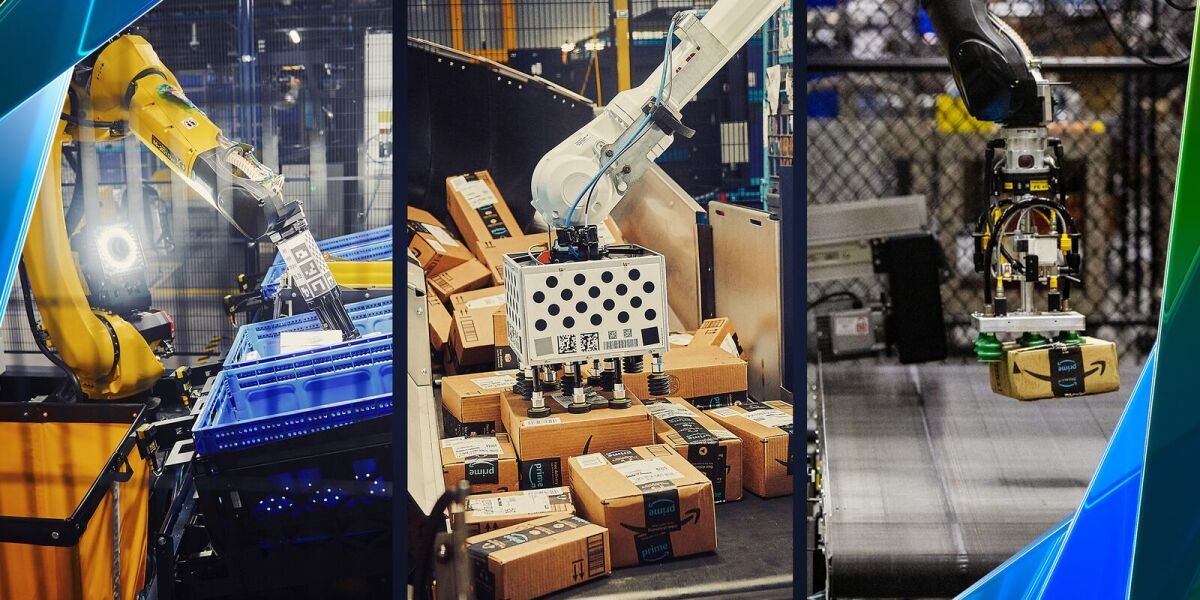

The expansion will also include an automated warehouse and new converting lines to turn the tissue into finished projects. Company President Robert K. Irving said the pulp to supply the additional paper machine would come from Irving's pulp mill in Saint John, New Brunswick, with wood supplied from timberland the company owns in New Brunswick and Maine.

The warehouse is scheduled to be complete in 2026, and the new paper machine is scheduled to be complete in 2027, Doucette said.

The factory was originally built with one paper machine, but added a second machine at the time it opened in 2019.

The Macon plant currently produces 165,000 tons (150,000 metric tons) of tissue per year. Once the addition is complete, the plant will make 248,000 tons (225,000 metric tons).

Workers at the plant make from $22 an hour to more than $30 an hour, Doucette said. That works out to a wage range of $45,760 a year to more than $62,400 a year.

Irving could qualify for $2 million in state income tax credits, at $4,000 per job over five years, as long as workers earn at least $35,600 a year. Macon-Bibb County could also grant property tax breaks on Irving's equipment and property. Doucette said the company is in talks about tax abatements and other possible incentives.

Irving Tissue is based in Dieppe, New Brunswick and is part of a family-owned industrial conglomerate that also includes an oil company, railroads, media and shipyards.

HISTORY

Irving Tissue Company Limited is a tissue products producing company, owned by J.D. Irving Limited.[1] It has manufacturing locations in both Canada and the United States.

Irving Tissue was started in 1988 in Saint John, New Brunswick after J.D. Irving acquired a tissue paper mill from Kimberly-Clark in the city's west side (adjacent to Irving Pulp and Paper).[2] Irving began producing tissue for a new subsidiary that was located in Moncton, N.B. and was sold under the marketing name Majesta.

In 1990, J.D. Irving opened a tissue-converting plant for Majesta in Dieppe, New Brunswick that would make use of the tissue produced in Saint John. Irving began producing private-label tissue products and the Majesta brand was launched in Canada.[2]

In 1996, Irving acquired another tissue paper mill from Kimberly-Clark as well as a tissue converting plant, both located in Fort Edward, New York. Part of this acquisition saw Irving Tissue receive the right to market its products under the Scotties Facial Tissue brand in the United States.[2]

In 2001, J.D. Irving acquired a tissue production and converting plant in Toronto from Procter & Gamble. This acquisition saw Irving Tissue receive the right to market the Royale brand in Canada.

In 2004, Irving Personal Care opened a New Brunswick plant to produce private-label baby diapers and training pants for major North American retailers.[2]

In 2010, major investments in buildings and a new through air-dried paper machine at the Irving Tissue site in Fort Edward increased capacity and improved product quality.

In 2019, Irving opened a new tissue mill and converting facility in Macon, Georgia. This facility uses the through air dried paper technology to produce bathroom tissue and paper towels.

Currently, Irving Tissue manufactures products under the Majesta and Royale brands in Canada and the Scotties brand in the United States.[1] (Another Canadian company, Kruger Inc., owns the Canadian rights to the Scotties brand.)